Sintered silicon carbide is of significant importance to Sialon Ceramics Denmark ApS due to its hardness and thermal conductivity. The application of heat and pressure during the sintering process strengthens its characteristics in hostile situations. Consequently, the technique is of vital importance in a number of sectors, including aircraft, military, and semiconductor production, where efficiency and endurance are of the utmost importance. As industry needs shift, sintered silicon carbide products are able to demonstrate there adaptability in expert industrial applications.

Definition and Explanation of Sintering

Sialon Ceramics LTD defines sintering of silicon carbide as a high-temperature technique that densifies powdered materials into solids using heat and pressure. Sintering involves atomic diffusion, whereby particles combine to form a stiff, dense structure without melting. It is used to create ceramic and metallic components with precise characteristics. For example, the temperatures used in ceramic sintering of silicon carbide range from 1000°C to 2000°C, depending on the material and the desired properties. The diffusion rates and particle size of the target material affect the sintering time, which can range from minutes to hours.

Silicon carbide (SiC), a non-oxide ceramic, has covalent bonding and a low self-diffusion coefficient, which makes sintering challenging. High-density sintered silicon carbide is manufactured at our facility using pressureless, hot pressing, and spark plasma sintering techniques. Inert atmospheres, such as argon, are employed to sinter SSIC at temperatures exceeding 1950°C in order to prevent oxidation. Additionally, boron carbide (B4C) or carbon (C) sintering aids may be incorporated into the manufacturing process of sintered silicon carbide. These additives facilitate its particle diffusion during sintering process of silicon carbide, resulting in enhanced thermal conductivity and hardness.

Other Industrial Applications

Aerospace Components:

Sintered silicon carbide components are vital in aircraft owing to their durability. We can make turbine components that use the material’s high-temperature stability and thermal shock resistance.

High-speed air travel requires such components that can tolerate temperatures beyond 1370°C. Their low density (3-3.2 g/cm³) also saves aircraft weight for fuel economy and performance. Satellite subsystems benefit from the material’s radiation resistance.

Automotive Parts:

The automotive industry has expanded with the incorporation of sintered silicon carbide in braking systems and engine components. The brake discs and pads exhibit unusual wear resistance and thermal conductivity for heat dissipation and performance under high-friction settings. Sintered silicon carbide can also be used to manufacture lightweight engine components that reduce the heat load and boost horsepower.

Ballistic Armour:

Sintered silicon carbide’s hardness and density are well-suited to vehicle and personal protection systems. We can produce ballistic armour plates that absorb and distribute impact energy, thereby enhancing the safety of military and law enforcement personnel. Such plates have been proven to fulfill the strict national military requirements, to guard against high-velocity projectiles, and to be key to current protective gear. Their lightweight design preserves mobility, giving tactical advantages in numerous military settings.

Semiconductor Devices:

Finally, SSIC is desirable in the semiconductor sector for high-power electronic devices. Its heat dissipation and structural stability at high temperatures render it advantageous in LED lighting systems and power semiconductors. The incorporation of SSIC into electronic devices enhances their reliability while simultaneously reducing thermal stress and extending their operational lifespan. This is particularly beneficial in the context of contemporary electronic applications.

In laboratories, our carbide crucibles are essential for high-temperature tests and chemical reactions, as they can withstand temperatures of up to 1900°C without deformation or chemical attack.

Foundries rely on these crucibles to handle molten metals, including aluminium and bronze, due to their low thermal expansion coefficient (3.2 x 10^-6/K) and porosity, which reduces the risk of thermal shock. Their resistance to oxidation and corrosion expands their usefulness compared to other materials. This minimises contamination concerns and maximises productivity.

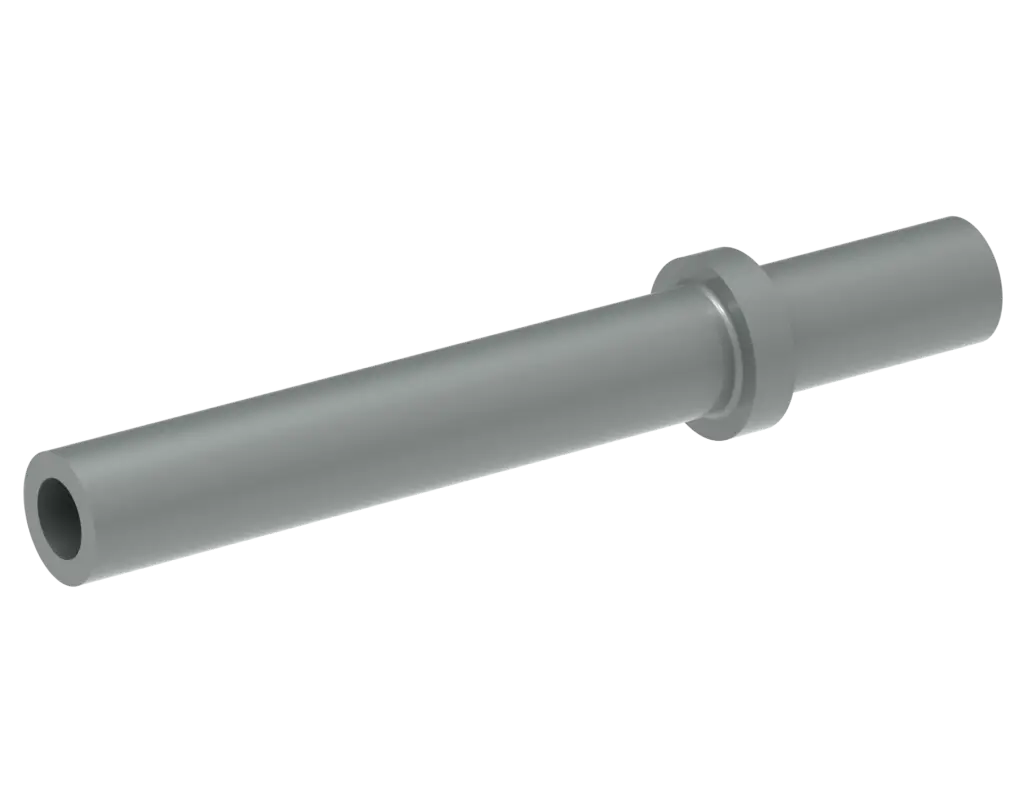

Thermocouple Protection Tubes:

SSIC thermocouple protection tubes are necessary for precise temperature monitoring in severe situations. They protect thermocouples from corrosive gases, abrasive particles, and high temperatures for accurate readings and sensor life. Our sintered silicon carbide thermocouple protection tubes help monitor the exact temperature in blast furnaces and incinerators, where temperatures may reach 1700°C. Their high mechanical strength and thermal shock tolerance are key to decreasing sensor failure interruptions and maintenance costs in challenging environments.

Custom-Made Products

We engage in bespoke sintered silicon carbide products for particular industry needs, including:

The addition of sintering additives may result in the introduction of impurities that can impair the mechanical qualities of the material. Therefore, it is essential to improve the powder particle size distribution and to manage the sintering environment in order to minimise chemical reactions and phase transitions.

Recent Technological Advancements in the Sintering Process

The incorporation of Spark Plasma Sintering (SPS) technology represents a promising avenue for further advancements in the sintering process. This technology allows for densification at lower temperatures and faster times than traditional methods, thereby reducing energy consumption and increasing throughput. SPS facilitates the control of grain development, resulting in improved hardness and fracture toughness. In our novel technique, we use computer simulations to forecast and alter processing settings contemporaneously, thereby achieving the finest density and characteristics. Such upgrades increase product quality and broaden the applications of sintered silicon carbide in extreme-condition sectors.

Future Prospects and Ongoing Research in Material Enhancement

Our subsequent research focuses on nanostructuring SSIC for its performance. We modify grain boundary chemistry and mechanics by incorporating nanoscale secondary phases to enhance oxidation and thermal shock resistance. Additionally, we are investigating hybrid composites, which combine silicon carbide with different ceramics or metallic phases to create materials with specific properties. This ongoing analysis facilitates the development of new markets and positions us as a leading authority in novel ceramic solutions while expanding the boundaries of SSIC.

Should you require further information regarding sintered silicon carbide properties or wish to discuss custom solutions, please do not hesitate to contact us.

Invalid number

Sweden / Sverige

+(46) 31 754 0790

Invalid number

Denmark

+(45) 35 15 8085

Invalid number

USA/Canada Tollfree

+ 1 (833) 709-1399

Invalid number

©2025 All Rights Reserved. Sialon Ceramics Denmark ApS