Description

The Role of Sialon Ceramic Ladles in the Aluminum Industry: Unmatched Durability and Performance

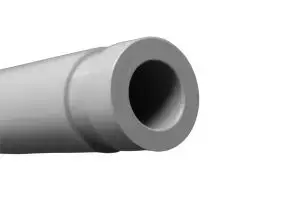

Introduction: In the fast-paced and high-stakes world of aluminum manufacturing, selecting the right materials for tooling and equipment is crucial. Among the numerous options available, Sialon ceramic ladles stand out as a preferred choice. These ladles, composed of silicon nitride-based ceramics, provide superior durability and performance in some of the harshest conditions found in aluminum casting and processing.

What is Sialon Ceramic? Sialon is a family of advanced ceramic materials primarily composed of silicon nitride (Si₃N₄), aluminum oxide (Al₂O₃), and other reinforcing additives. Sialon ceramics are engineered to withstand extreme temperatures, wear, and chemical corrosion, making them ideal for industries like aluminum manufacturing, where high thermal and mechanical stresses are common.

Durability in Extreme Conditions:

-

High Temperature Resistance: Sialon ceramic ladles are capable of withstanding the high temperatures encountered during the aluminum casting process. Unlike traditional ladles made from metal or other ceramics, Sialon maintains its structural integrity at temperatures exceeding 1,600°C (2,912°F). This heat resistance prevents deformation or failure during extended use, ensuring consistent performance in aluminum molten metal handling.

-

Thermal Shock Resistance: One of the critical challenges in the aluminum industry is the frequent temperature fluctuations experienced during metal pouring and cooling. Sialon’s excellent thermal shock resistance allows it to endure sudden changes in temperature without cracking or warping, a frequent issue with less advanced materials. This makes it a reliable tool that improves the efficiency and safety of aluminum processing operations.

-

Wear and Abrasion Resistance: The continuous exposure to molten aluminum, which is abrasive and corrosive, can cause significant wear on traditional ladles. Sialon ceramic ladles are resistant to such abrasion, providing long service lives even when handling large volumes of molten aluminum. Their resistance to erosion reduces the frequency of maintenance and replacement, ultimately lowering operational costs for manufacturers.

-

Chemical Stability: Sialon’s resistance to chemical attack further enhances its durability. Molten aluminum can contain various alloys and impurities, some of which may react aggressively with common ladle materials. Sialon ceramic ladles are less susceptible to chemical degradation, ensuring that the ladle’s integrity remains intact throughout the casting process, regardless of the chemical composition of the molten metal.

Advantages Over Traditional Ladles:

- Longevity: Sialon ladles are designed for long-lasting use, far outpacing the service life of their metal counterparts. This minimizes downtime for maintenance and part replacements, providing a more cost-effective solution for aluminum foundries.

- Efficiency: The superior thermal properties of Sialon ladles help to maintain more consistent temperatures in the molten aluminum, contributing to better control over the casting process and improving product quality.

- Safety: By reducing the risks associated with thermal shock, wear, and chemical corrosion, Sialon ladles contribute to a safer working environment for aluminum industry professionals.

Conclusion: In the aluminum industry, where precision, durability, and cost-efficiency are paramount, Sialon ceramic ladles provide an invaluable solution. Their exceptional heat resistance, thermal shock resilience, and chemical stability make them indispensable tools for aluminum casting, ensuring not only improved operational efficiency but also a safer, more sustainable manufacturing process. For companies looking to push the boundaries of performance and reliability in their aluminum production processes, Sialon ceramic ladles are a smart investment.

| Material data sheet | Sialon (Si3Al3O3N5) | ||||

Typical Sialon ULTRA™ grades |

ULTRA-001 | ULTRA-002 | ULTRA-003 | ULTRA-004 | |

| Bulk Density | g/cm3 | 3.2 | 3.1 | 3.3 | 3.2 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Flexural Strength | MPa | 580 | 900 | 1,020 | 790 |

| Vickers Hardness HV1 | GPa | 13.9 | 12.7 | 15.0 | 13.8 |

| Fracture Toughness (SEPB) | MPam1/2 | 4 ~ 5 | 6 ~ 7 | 7 | 6 ~ 7 |

| Young’s Modulus of Elasticity | GPa | 290 | 270 | 300 | 290 |

| Poisson’s Ratio | – | 0.28 | 0.28 | 0.28 | 0.28 |

| Coefficient of Linear Thermal (40 – 800 °C) Expansion |

×10-6/℃ | 3.2 | 3.4 | 3.3 | 3.5 |

| Thermal Conductivity (20℃) | W/(m・k) | 25 | 23 | 27 | 54 |

| Specific Heat | J/(g・k) | 0.64 | 0.66 | 0.65 | 0.66 |

| Heat Shock Resistance | ℃ | 550 | 800 | 800 | 900 |

| Volume Resistivity (20℃) | Ω・cm | >1014 | >1014 | >1014 | >1014 |