- English

- Home

- About Us

- Sialon Ceramics

- SSiC Ceramics

- Sialon ULTRA™ Products

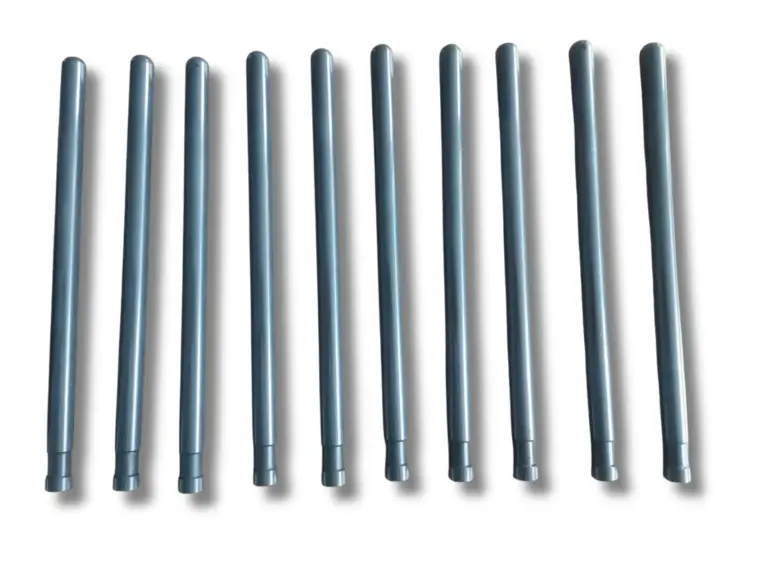

- Sialon (Immersion) Heater Tubes

- Thermocouple Protection Tubes

- Low Pressure Die casting

- High Pressure Die Casting

- Degassing molten Aluminium

- Other Sialon Products

Sialon ULTRA™A new generation of Sialons with an increased impact fracture toughness up to 1.400° Celsius / 2624° Fahrenheit.

- XICAR® SSiC ProductsXICAR™ Sintered Silicon Carbide

A new generation of Sintered Silicon Carbide with superior or equal performance to HEXOLOY® | For use in molten metals up to 1900 °Celsius

- Online Meeting

- Contact Us

- Client Portal

- Shop