Product Description

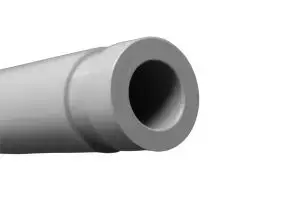

Sialon & Silicon Nitride Striko Sialon Westofen Dosing Tubes give the best price/performance rate when melting temperature of aluminum at 660.3 °C.

The Westomat crucible dosing furnace is a clean, closed warming and dosing system for liquid aluminum. Depending on the system, the metal is always removed below the surface of the bath and is therefore automatically fed to the casting machine or casting mold free of contaminants.

Setting up and operating the system is easy with the silicon nitride Striko Sialon Westofen dosing tubes. And that with extremely low cleaning and maintenance costs. Its lifespan is proverbial: Our customers still use our riser tubes after 2-3 years in service. The Westomat furnace can also be heated with Sialon Immersion heaters. It can be integrated into any die casting system, but also in gravity casting. With variants from 450 kg to 3,100 kg capacity, the Westomat covers all cast part sizes.The hydrogen content of the molten aluminium can now be easily measured by using our new hydrogen content measurement device which has been optimized for ultrasonic degassing.

| Material data sheet | Sialon (Si3Al3O3N5) | ||||

Typical Sialon ULTRA™ grades |

ULTRA-001 | ULTRA-002 | ULTRA-003 | ULTRA-004 | |

| Bulk Density | g/cm3 | 3.2 | 3.1 | 3.3 | 3.2 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Flexural Strength | MPa | 580 | 900 | 1,020 | 790 |

| Vickers Hardness HV1 | GPa | 13.9 | 12.7 | 15.0 | 13.8 |

| Fracture Toughness (SEPB) | MPam1/2 | 4 ~ 5 | 6 ~ 7 | 7 | 6 ~ 7 |

| Young’s Modulus of Elasticity | GPa | 290 | 270 | 300 | 290 |

| Poisson’s Ratio | – | 0.28 | 0.28 | 0.28 | 0.28 |

| Coefficient of Linear Thermal (40 – 800 °C) Expansion |

×10-6/℃ | 3.2 | 3.4 | 3.3 | 3.5 |

| Thermal Conductivity (20℃) | W/(m・k) | 25 | 23 | 27 | 54 |

| Specific Heat | J/(g・k) | 0.64 | 0.66 | 0.65 | 0.66 |

| Heat Shock Resistance | ℃ | 550 | 800 | 800 | 900 |

| Volume Resistivity (20℃) | Ω・cm | >1014 | >1014 | >1014 | >1014 |