Description

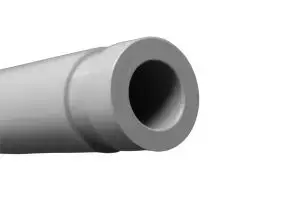

Sialon Silicon Nitride Extrusion Dies for the Aluminium Industry

Sialon silicon nitride extrusion dies are engineered for exceptional performance in the demanding aluminium extrusion process. Known for their unmatched durability, these dies are designed to withstand the extreme conditions of high temperatures and high-pressure environments typically encountered in aluminium processing. Made from advanced Sialon materials, these dies offer superior resistance to wear, corrosion, and thermal shock, which leads to longer tool life and reduced maintenance costs.

The unique properties of Sialon silicon nitride ensure that these dies retain their structural integrity and precision even under the most intense operational conditions. Their excellent thermal conductivity aids in consistent temperature regulation, ensuring smoother and more efficient extrusion of aluminium profiles. Furthermore, the low coefficient of friction of Sialon reduces the wear on both the dies and the aluminium material, enhancing the overall quality and finish of the extruded products.

Whether used in standard or complex extrusion applications, Sialon silicon nitride extrusion dies deliver outstanding durability, reducing downtime, and improving production efficiency. Ideal for high-volume aluminium extrusion plants, these dies are a reliable investment that will provide long-term, cost-effective performance.

| Material data sheet | Sialon (Si3Al3O3N5) | ||||

Typical Sialon ULTRA™ grades |

ULTRA-001 | ULTRA-002 | ULTRA-003 | ULTRA-004 | |

| Bulk Density | g/cm3 | 3.2 | 3.1 | 3.3 | 3.2 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Flexural Strength | MPa | 580 | 900 | 1,020 | 790 |

| Vickers Hardness HV1 | GPa | 13.9 | 12.7 | 15.0 | 13.8 |

| Fracture Toughness (SEPB) | MPam1/2 | 4 ~ 5 | 6 ~ 7 | 7 | 6 ~ 7 |

| Young’s Modulus of Elasticity | GPa | 290 | 270 | 300 | 290 |

| Poisson’s Ratio | – | 0.28 | 0.28 | 0.28 | 0.28 |

| Coefficient of Linear Thermal (40 – 800 °C) Expansion |

×10-6/℃ | 3.2 | 3.4 | 3.3 | 3.5 |

| Thermal Conductivity (20℃) | W/(m・k) | 25 | 23 | 27 | 54 |

| Specific Heat | J/(g・k) | 0.64 | 0.66 | 0.65 | 0.66 |

| Heat Shock Resistance | ℃ | 550 | 800 | 800 | 900 |

| Volume Resistivity (20℃) | Ω・cm | >1014 | >1014 | >1014 | >1014 |